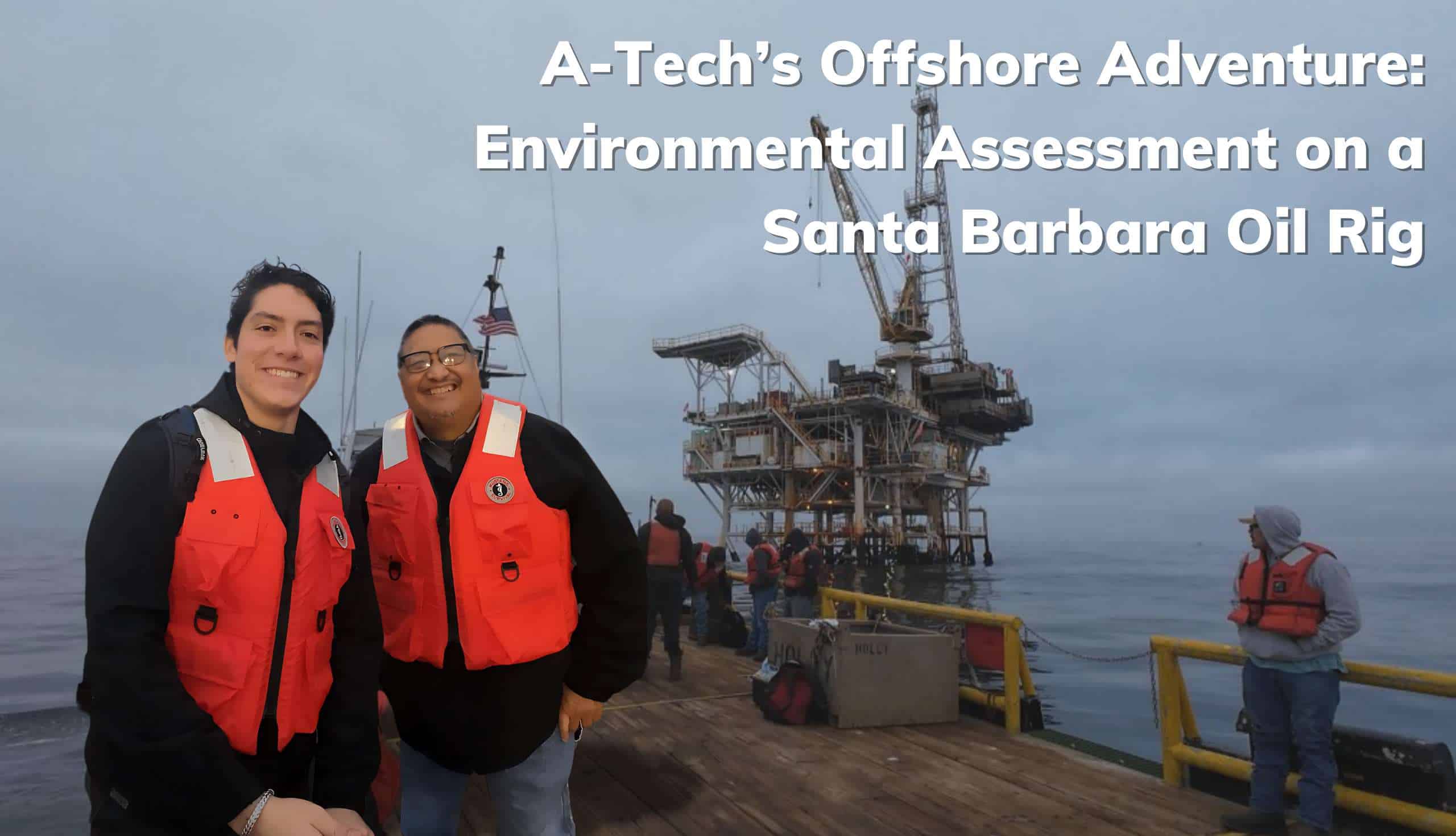

A-Tech’s Offshore Adventure: Environmental Assessment on a Santa Barbara Oil Rig

When A-Tech Consulting was called to assess environmental hazards on an offshore oil rig near Santa Barbara, we knew this job would be unlike any other. Situated two miles out at sea, the rig required us to take on a few unique challenges, including swing rope training for a safe transfer from the boat to the platform—a far cry from the typical elevator ride!

Over the course of two days, our team completed a thorough assessment, addressing four critical environmental tasks. Here’s how we ensured the safety and compliance of the rig.

Task 1: Asbestos Assessment

Our first priority was to conduct a comprehensive asbestos inspection, adhering to strict Cal-OSHA and NESHAP guidelines. A Certified Asbestos Consultant (CAC) led our team in inspecting building materials across the rig, collecting samples from any areas suspected of containing asbestos.

We sent these samples to a lab for a 24-hour expedited analysis. Once we received the results, we created a detailed report identifying the locations of asbestos on the rig and provided tailored recommendations for safe removal or management.

Task 2: Lead Assessment

Next, our focus shifted to assessing lead levels. Using advanced X-Ray Florescence (XRF) technology, our CDPH Lead Inspector Assessor scanned painted surfaces and other materials, such as ceramics and porcelain, across the platform for lead content. When XRF readings were inconclusive, we took samples for further lab analysis.

Within 24 hours, we produced a report outlining lead concentrations and offered remediation suggestions where necessary.

Task 3: PCB Assessment

Polychlorinated Biphenyls (PCBs) were also a potential concern. Our team collected bulk and liquid samples from equipment and materials suspected of containing PCBs. These were analyzed in accordance with EPA regulations, with our Certified Industrial Hygienist (CIH) compiling the findings into a detailed technical report.

If PCBs were detected, we provided actionable steps for safe handling and removal.

Task 4: Mercury Vapor Screening

Finally, we performed a mercury vapor screening using a specialized Mercury Vapor Analyzer (MVA). We carefully checked the rig’s equipment for any abnormal mercury levels. Although no significant levels of mercury were detected, our team was ready to take further action if needed, including follow-up assessments for flagged equipment.

The Outcome

In just two days, A-Tech Consulting successfully completed all required assessments and delivered comprehensive reports to the client. From asbestos and lead to PCBs and mercury, our team ensured the rig met environmental compliance standards with precision and efficiency.

While the offshore setting added some excitement with swing rope training and boat rides, the real adventure lay in executing a complex project while upholding A-Tech’s high standards of safety, accuracy, and reliability. Whether on land or sea, A-Tech Consulting is always ready to deliver!

To see a full list of services A-Tech has to offer, click here. If you have any questions in regards to Environmental assessments, trainings or regulations feel free to reach out to us by clicking here.